Unlocking the Power of IoT in Supply Chain Management

In today's complex and interconnected world, supply chain visibility is no longer a luxury, but a necessity. Companies are constantly seeking ways to improve efficiency, reduce costs, and enhance customer satisfaction. The Internet of Things (IoT) has emerged as a game-changer, offering unprecedented opportunities to achieve real-time visibility and control across the entire supply chain.

What is IoT and How Does it Relate to Supply Chain?

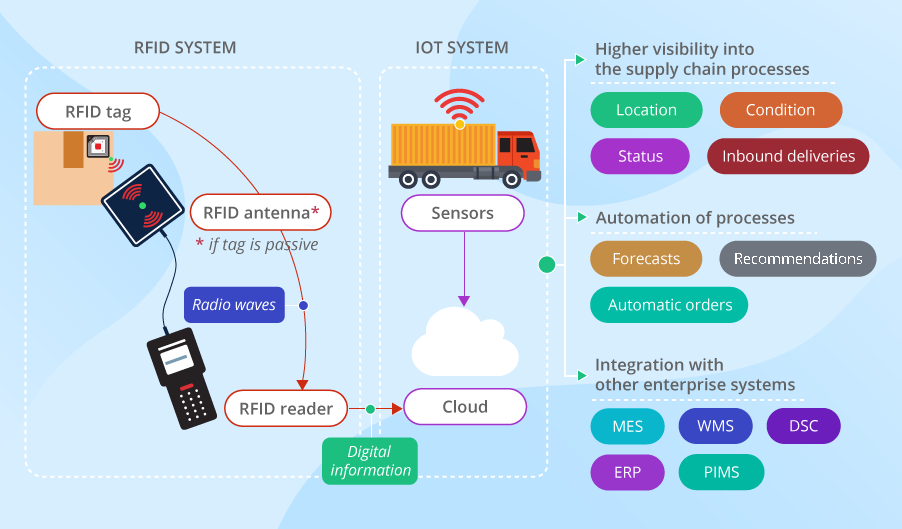

The Internet of Things refers to the network of physical objects – “things” – embedded with sensors, software, and other technologies for the purpose of connecting and exchanging data with other devices and systems over the internet. In the context of the supply chain, these "things" can be anything from individual products and pallets to vehicles, warehouses, and even personnel.

By connecting these elements and leveraging the data they generate, IoT enables businesses to gain a comprehensive and granular view of their supply chain operations. This enhanced visibility allows for better decision-making, proactive risk management, and improved overall performance.

Key Benefits of IoT for Smart Supply Chain Visibility

Implementing IoT solutions in your supply chain can unlock a multitude of benefits, including:

Real-Time Tracking and Monitoring

IoT sensors can track the location, condition (temperature, humidity, shock), and status of goods in transit, providing real-time updates throughout the supply chain. This eliminates blind spots and enables businesses to proactively address potential disruptions, such as delays or damage.

Improved Inventory Management

IoT-enabled inventory management systems can track stock levels in real-time, optimize warehouse layouts, and automate replenishment processes. This reduces stockouts, minimizes waste, and improves overall inventory accuracy.

Enhanced Predictive Maintenance

By monitoring the performance of equipment and machinery using IoT sensors, businesses can predict potential failures and schedule maintenance proactively. This minimizes downtime, extends the lifespan of assets, and reduces maintenance costs.

Optimized Logistics and Transportation

IoT solutions can optimize transportation routes, track vehicle performance, and monitor driver behavior. This reduces fuel consumption, improves delivery times, and enhances overall logistics efficiency.

Increased Transparency and Traceability

IoT enables businesses to track the provenance of products, ensuring authenticity and compliance with regulatory requirements. This is particularly important in industries such as food and pharmaceuticals, where traceability is critical for safety and quality.

Data-Driven Decision Making

The vast amounts of data generated by IoT devices can be analyzed to identify trends, patterns, and areas for improvement. This data-driven approach enables businesses to make informed decisions, optimize processes, and drive continuous improvement.

Examples of IoT Applications in Supply Chain

The application of IoT in supply chain is diverse and constantly evolving. Here are some specific examples:

Smart Warehousing

IoT sensors can monitor environmental conditions, track inventory levels, and automate warehouse operations. This improves efficiency, reduces costs, and enhances safety.

Connected Transportation

GPS trackers, sensors, and telematics systems provide real-time visibility into the location, condition, and performance of vehicles. This enables businesses to optimize routes, monitor driver behavior, and improve delivery times.

Cold Chain Monitoring

Temperature sensors and data loggers monitor the temperature of perishable goods throughout the supply chain, ensuring that they remain within safe limits. This prevents spoilage and reduces waste.

Asset Tracking

RFID tags and GPS trackers can track the location and status of valuable assets, such as equipment, machinery, and containers. This prevents theft, reduces loss, and improves asset utilization.

Predictive Maintenance for Manufacturing

Sensors on manufacturing equipment monitor vibration, temperature, and other parameters to predict potential failures. This allows for proactive maintenance, minimizing downtime and extending the lifespan of assets.

Challenges of Implementing IoT in Supply Chain

While the benefits of IoT in supply chain are significant, there are also challenges to consider:

Data Security and Privacy

IoT devices generate vast amounts of data, which must be protected from unauthorized access and cyberattacks. Implementing robust security measures is crucial to ensure the confidentiality, integrity, and availability of data.

Interoperability and Standardization

Different IoT devices and systems may use different communication protocols and data formats, making it difficult to integrate them seamlessly. Standardizing protocols and data formats is essential for interoperability.

Scalability and Cost

Implementing IoT solutions can be expensive, particularly for large and complex supply chains. Businesses need to carefully consider the scalability and cost-effectiveness of their IoT deployments.

Data Management and Analytics

The vast amounts of data generated by IoT devices can be overwhelming. Businesses need to have the infrastructure and expertise to manage, analyze, and interpret this data effectively.

Skills Gap

Implementing and managing IoT solutions requires specialized skills in areas such as data analytics, cybersecurity, and network engineering. Businesses may need to invest in training or hire new talent to address the skills gap.

Getting Started with IoT for Supply Chain Visibility

If you are considering implementing IoT solutions in your supply chain, here are some steps to get started:

Define Your Objectives

Clearly define your goals and objectives for implementing IoT. What problems are you trying to solve? What improvements are you hoping to achieve?

Identify Key Use Cases

Identify specific use cases where IoT can have the greatest impact on your supply chain. Focus on areas where you can achieve quick wins and demonstrate the value of IoT.

Choose the Right Technology

Select the right IoT devices, platforms, and software for your specific needs. Consider factors such as cost, scalability, security, and interoperability.

Develop a Data Management Strategy

Develop a comprehensive data management strategy that addresses data collection, storage, processing, and analysis. Ensure that you have the infrastructure and expertise to manage the vast amounts of data generated by IoT devices.

Implement Security Measures

Implement robust security measures to protect your IoT devices and data from cyberattacks. This includes encrypting data, implementing access controls, and regularly patching software.

Pilot and Scale

Start with a pilot project to test your IoT solutions and validate their effectiveness. Once you have proven the value of IoT, you can gradually scale your deployments across your supply chain.

The Future of IoT in Supply Chain

The future of IoT in supply chain is bright. As technology continues to evolve and costs continue to decline, we can expect to see even more widespread adoption of IoT solutions. Emerging trends such as 5G, artificial intelligence (AI), and blockchain will further enhance the capabilities of IoT and enable even greater levels of visibility, efficiency, and resilience in the supply chain.

0 Comments